The solution is to spread your unsized bullets out and fog lightly with whatever dry spray lube you have on hand. One other slight problem with Star sizers is that the bullets are sized dry, with lube injected after sizing, which makes sizing extremely difficult with large bullets having a hardness of 20+ bhn. 001 inch for sizing to prevent this leakage problem. When using a Star Sizer, order your mold to allow. You won't have trouble with blue soft at temps up to at least 120 deg if attention is paid to how tight the lube screw is tightened. Blue soft works great at temps down to 40 deg F, but in warm work areas, apply less lube pressure to avoid leakage between bullets which will leave a streak of lube on the nose. Commercial is nicest if you have a heater. LBT Blue will run great at room temperatures without a heater. You'll have to apply lube pressure a bit more often while it is solidifying, but otherwise you won’t know it’s melted. Don’t wait for the lube to harden, just go right to sizing. If you happen to have hollow LBT lubes and some other brands which are not harmed by melting, you can melt and pour into the sizer, with any sizer in fact. Star Sizers can use hollow sticks, but are designed for solid, and you get a bit more lube for your money while avoiding trapped air problems.

#Star luber sizer how to#

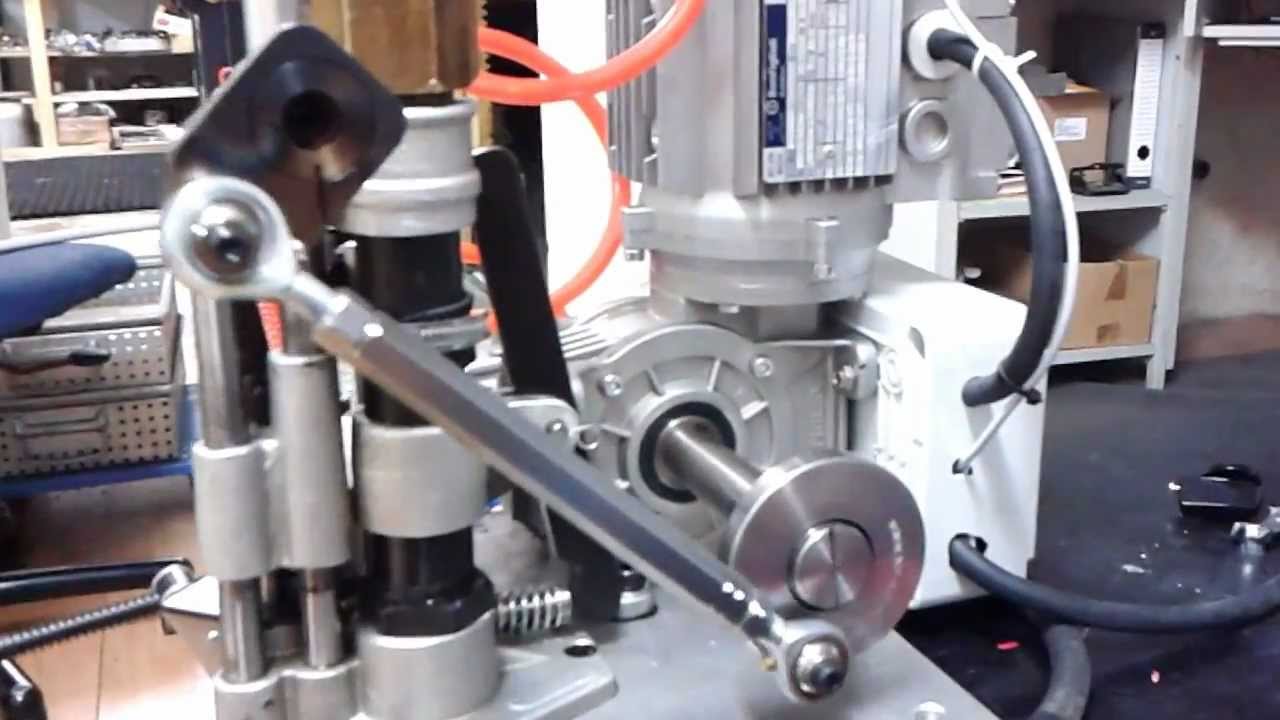

I'll explain how to get the same results in the other sizers in a minute, after discussing which LBT lube to use in Star Sizer. It does not work with plain base bullets in the Star, so if you want to process un-gaschecked bullets in a Star sizer, choosing a bevel base and pushing them through nose first works quite well, because the bevel edge isn’t affected by shrink like the flat bottom is, as is described below. That’s not a problem with LBT molds because we guarantee a slip on gas check fit, which prevents checks from shaving and going off center at all, and unlike cherried molds, our check shanks are perfectly concentric to the bullet.Īt any rate, this tiny, and probably invisible bit of press formed precision can shrink groups from 2-3 inches down to tack holes! DO NOT OVER LOOK IT! A punch of this description pushes GC’s on if they are a bit tight, then sizes them on with perfect concentricity to the bullet body, and perfect squareness around the critical perimeter of the heel.īy contrast, the other sizers crimp the GC on before any of the bullet enters the die, so if the check shank has any deformities, or if the check shaves lead a bit on one side when pressed on, the check, being far stronger than lead, will force the bullet to size out of balance at the base end. This so all pressure is applied around the outer edge of the GC base, straddling any raised sprue etc. Then its end needs to be cupped out a few thousandths so only about a 1/32 inch wide contact ring is left around the perimeter. To take advantage of the Star's potential with gas checked bullets, the pusher punch must be fairly close to sizer diameter, having about. They are the Rolls Royce of sizers, with tremendous lube injection pressure, to the point that it can cause leak problems if not understood, and production speed is about double what the other sizers put out.īullets are pushed straight through, with each new bullet pushing the preceding one out, which makes for problems with pointy spitzers. If you are going to purchase a sizer we recommend a Star (available from Magma engineering, Queen Creek, AZ) if you'll be sizing only gas checked flat nose bullets. Please study it carefully and you’ll probably gain helpful knowledge. I am writing it because it has been a large part of the technical phone conversations which have tied up so much of my time. Also important factors about which of our lubes to use. This section is to explain several very important facts about differences in functions, operation and quality of the lubricator sizers that are available. ( I mostly heat and pour lube into the lube/sizer ) But, want sticks too. press to push lube sticks out of the pvc tubes and put a hole in them at the same time. I think I have done it, I just need to test it being applied and shot first.

#Star luber sizer plus#

Plus I wanted to use inexpensive and readily available supplies.

It's slightly harder than the regular lubes like RCBS and Lymans etc. It was interesting trying to get it the right consistency, not too tacky or too hard and will work in my rcbs lube sizer with and without heat. I need to run it through my guns and see how it works now.

I just got through experimenting on some more lube recipes myself. I also made some Ben's Red last night - what a stench :( And圜 wrote:I've actually ordered a roller-handle from lathesmith ($28 shipped) - never used one of those and everyone says it's the bee's knees, so I figured what the heck, let's try it.

0 kommentar(er)

0 kommentar(er)